References

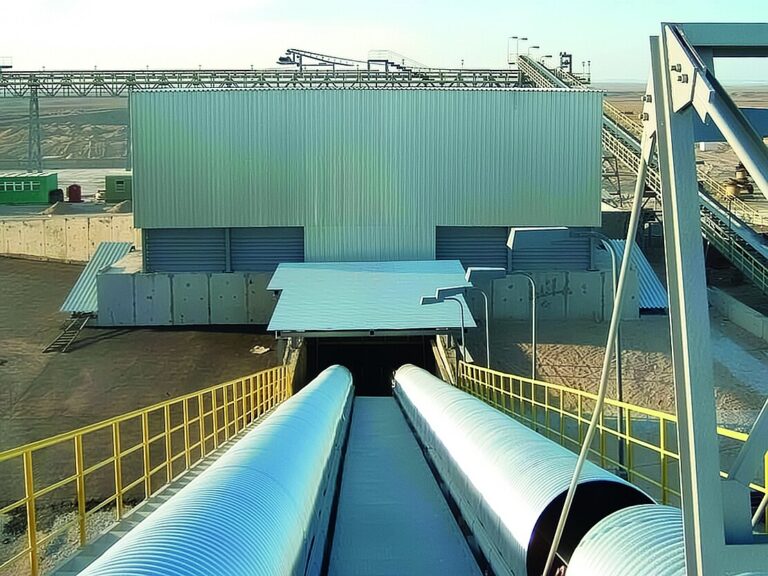

Once a dry desert landscape, now a state-of-the-art production facility – that is the story of the phosphate processing plant at the “Tashkura I” deposit in Uzbekistan. The plant was commissioned in May 2007 and has since enabled the efficient processing of phosphate ore with a capacity of up to 104 tons per hour. This advanced technology plays a key role in resource optimization and offers sustainable solutions for the region and the operator.

Commissioning: May 2007

- Client: Navoi Mining & Metallurgical Combinat (NGMK)

- Location: “Tashkura I” deposit, Uzbekistan

- Type of contract/services: Planning, delivery and installation of a new phosphate ore treatment plant

- Scope of delivery: Turnkey phosphate ore treatment plant

- Technical data: Production of 104 t/h of washed phosphate ore

Customer benefits

Reduced chloride concentration: Reduction from approx. 0.2 % to max. 0.033 %, which optimizes product quality.

Reduction in water consumption: Significant reduction in water consumption for resource-saving production.

Corrosion protection: Prevention of severe corrosion in the treatment plant due to the low chloride concentration.

With this modern phosphate processing plant, we are making a valuable contribution to the efficient use of phosphate ores and the sustainable conservation of resources in the region.

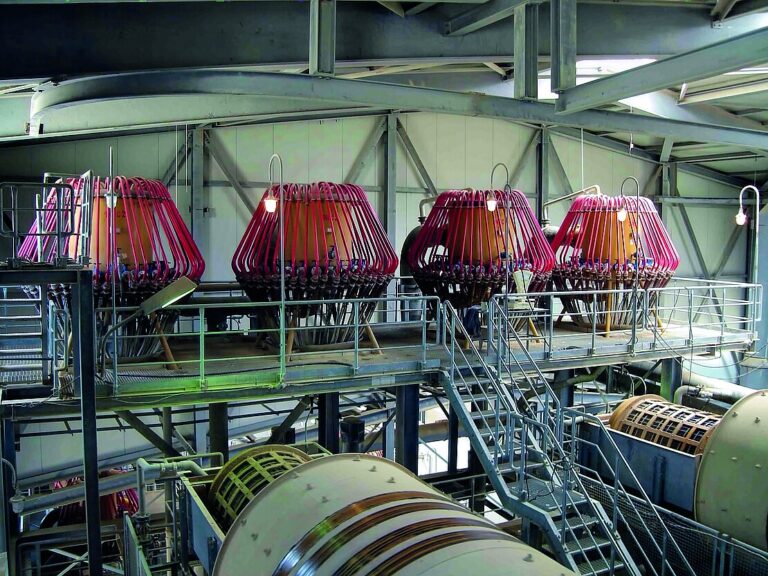

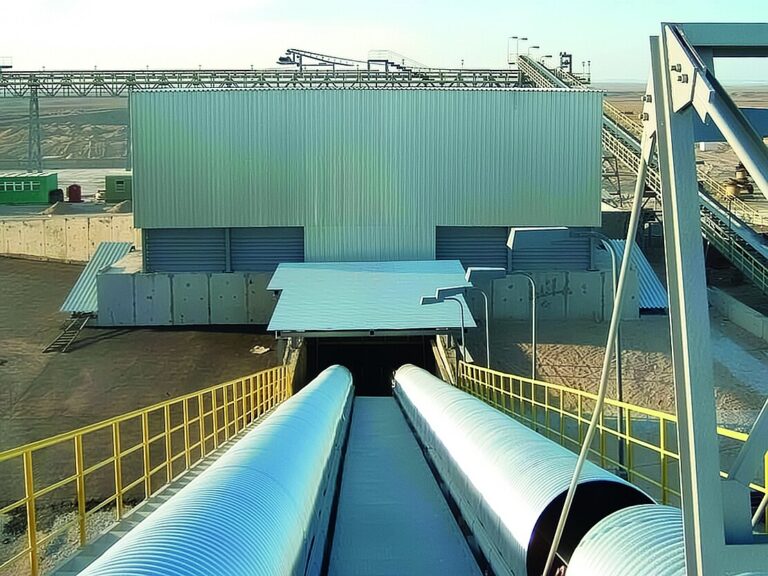

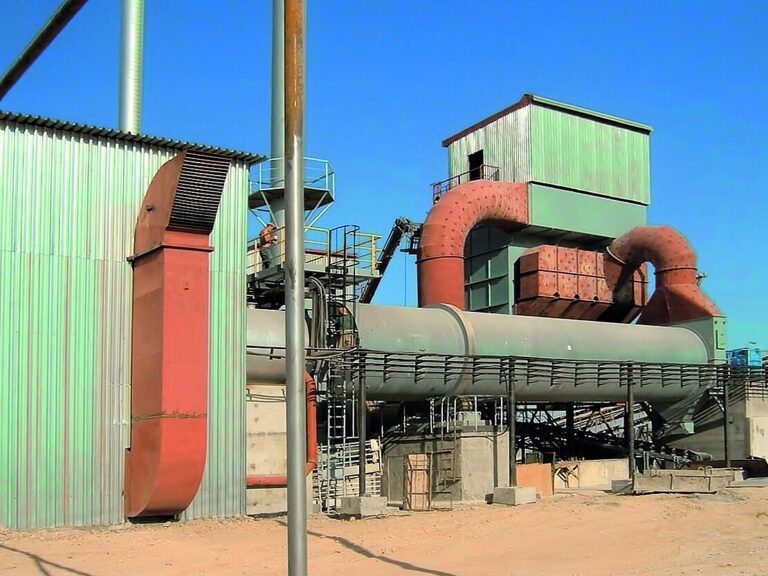

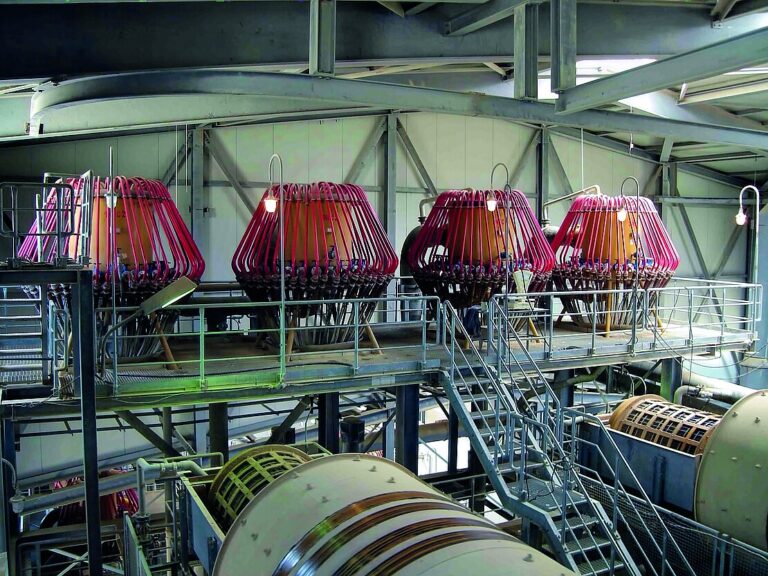

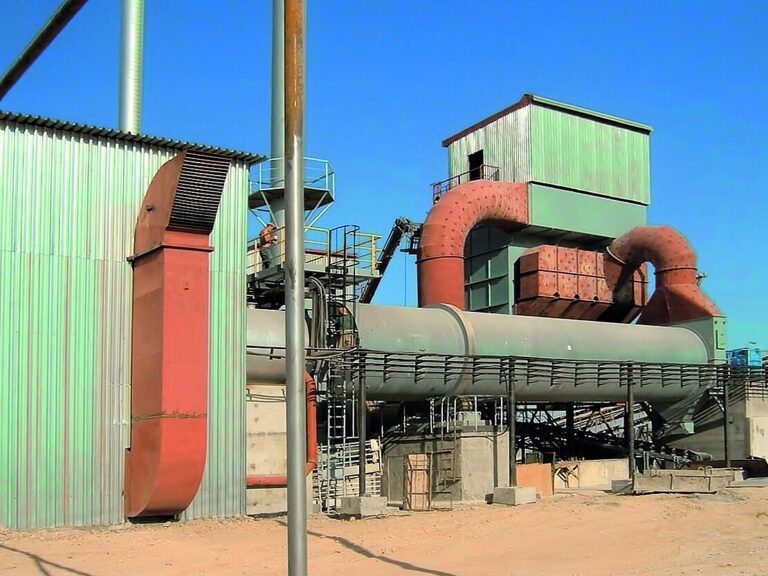

Following the successful “Tashkura I” phosphate processing plant project, we received the follow-up order to construct a calcination plant at the “Tashkura II” deposit. This expansion will increase the production capacity of the phosphate ore processing plant and ensure a continuous supply of raw materials for the industry. The commissioning of the calcination plant in September 2014 represented an important milestone in the optimization of phosphate ore processing technology.

Commissioning: September 2014

- Location: Tashkura II deposit, Uzbekistan

- Type of contract/services Basic and detail engineering, supervision of installation and commissioning, partial upgrade of the existing plant for phosphate ore processing, documentation according to GOST

- Scope of delivery: Calcination kiln, rotary drum dryer, 350 m conveyor belt system, bag filter, chimney, (material) hopper, feed hopper, auxiliary equipment

- technical data: Throughput of the calcination furnace: 52 t/h of concentrate, characteristics of the rotary drum dryer: 52 t/h of concentrate with a heat capacity of 13 MW

Customer benefits

Low investment costs: lower construction and installation costs compared to competitor systems

Energy efficiency: reduced energy consumption lowers operating costs

Simple operation: Minimal control effort makes operation easier

High product quality in one step: Reduces the number of processing steps

Minimal maintenance: longer operating times and less downtime

No moving parts: Increased reliability and longevity of the system

With our expertise in engineering and plant construction, we are making a decisive contribution to the sustainable extraction of raw materials in Uzbekistan.