References

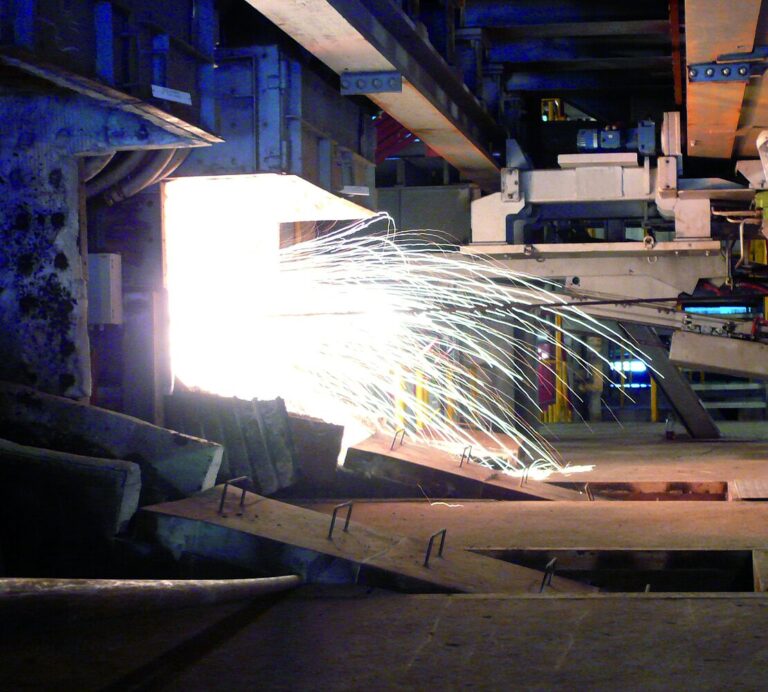

As part of a comprehensive project from 2006 to 2011, we – with Glencore International AG as the main investor – built a copper smelter with electrolysis for Kazzinc Ltd. and modernized and expanded the lead plant. The aim was to increase production capacity, improve efficiency and significantly reduce the environmental impact through innovative technologies.

Commissioning of copper smelter: 2011, lead works: 2012

- Client: Kazzinc Ltd (Glencore International AG)

- Location: Kazakhstan

- EP (Engineering, Procurement) plus coordination of the overall sulfuric acid production plant & weak acid concentration plant including

- Scope of delivery:

- Copper smelter: preparation of raw materials, gas cleaning and dust treatment, electric and anode furnaces, anode casting machine, systems for leaching and drying anode sludge, cooling water system and auxiliary media supply (compressed air, oxygen, nitrogen), fuel supply (heavy oil, diesel oil)

- Lead works: slag casting plant, dosing mold, electrostatic precipitator, gas duct system, ventilation and heating systems for the melting furnace hall

- Technical data:

- Copper smelter: Production of 87,500 tons of copper cathodes per year

- Lead works: production of 100,000 tons of lead per year

Customer benefits

Successful start to copper production: the new copper smelter meets the high efficiency and capacity requirements

Increased productivity in lead production: the modernization of the lead plant led to a significant improvement in production quality and quantity

Compliance with strict emission targets: The modernization has significantly reduced the emission of harmful substances compared to the old plant

Environmentally friendly processes: The exhaust gases from the lead plant are recycled in the production of sulphuric acid, which significantly reduces air pollution

environmental impact

With our expertise in the modernization and new construction of complex industrial plants, we have developed a forward-looking solution for Kazzinc Ltd. that not only increases efficiency but also reduces environmental impact.