References

The project to improve the technology for extracting gold from refractory ores at the Uchquduq deposit of Navoi Mining & Metallurgical Combinat (NGMK) in Uzbekistan represents a significant investment as part of NGMK’s development program. With the commissioning of the globally unique STR system – a sorption tailings roasting system – we were able to increase raw material efficiency by 8% and production by 11%. In addition, 150 new jobs were created.

- Client: Navoi Mining & Metallurgical Combinat (NGMK)

- Location: Uchquduq, Uzbekistan

- Contract type/services: Turnkey solution (technological part), total solution provision incl. design, delivery and commissioning

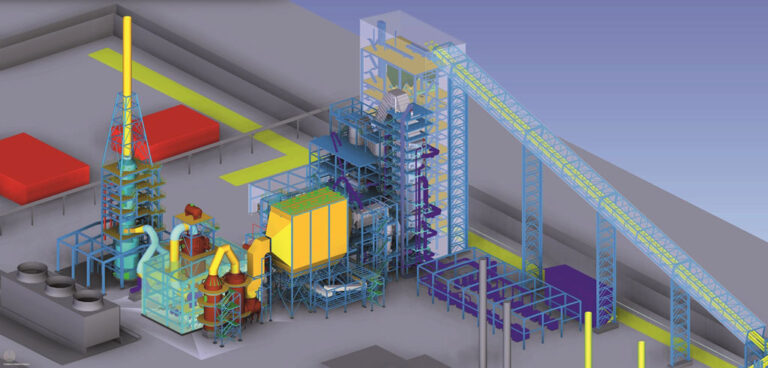

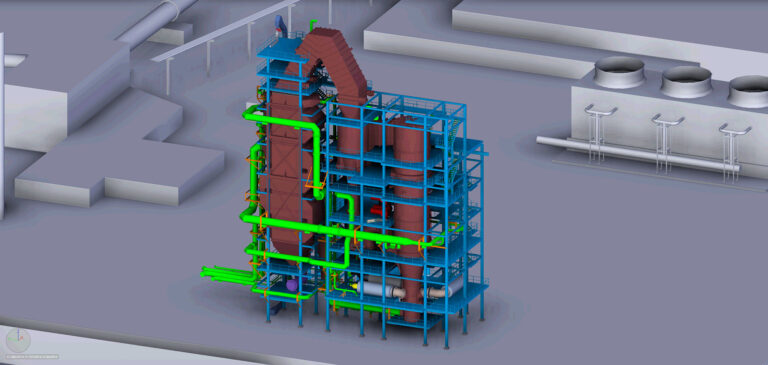

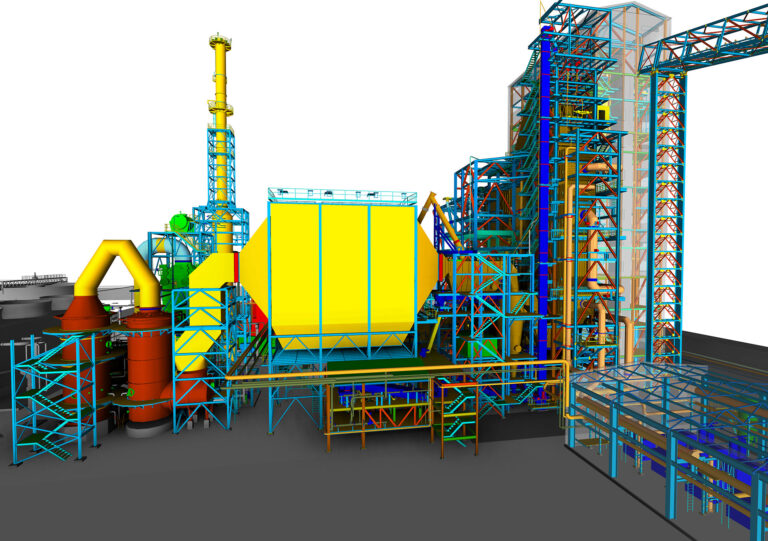

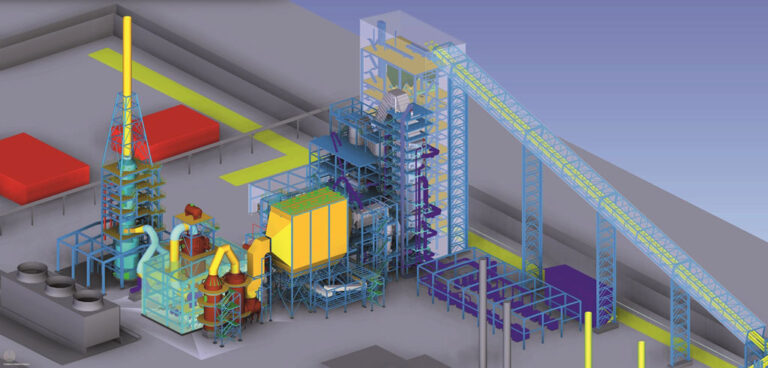

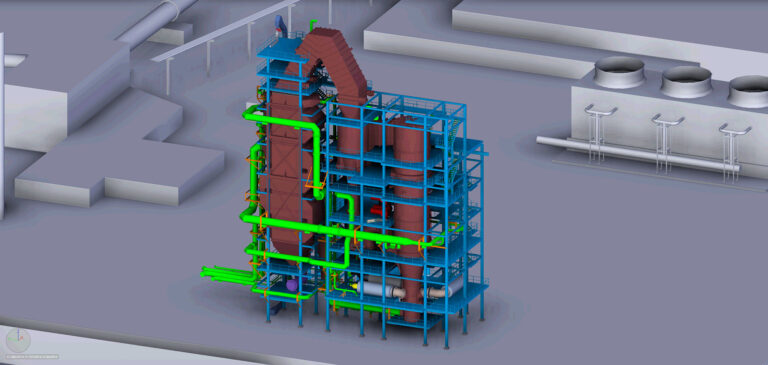

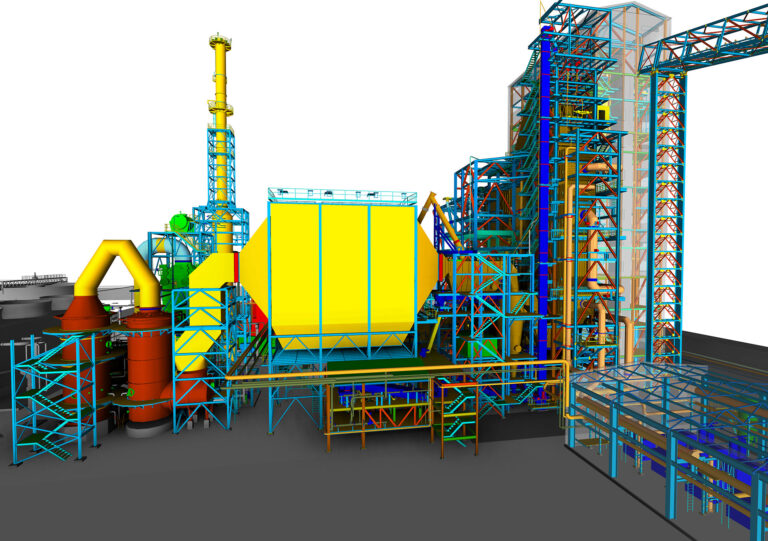

Complete process with patented STR system, basic and detailed design, supply of equipment, documentation, process control and automation, installation supervision and commissioning, staff training - Scope of delivery: Dewatering system, intermediate storage, drying and granulation of filter cake, circulating fluidized bed roasting furnace, exhaust gas dedusting, wet gas cleaning and desulphurization, cooling and grinding of the roasted material, cooling system, process and instrument air system, electrical equipment and measurement, control and regulation technology, automated control system

- Technical data: Feed capacity up to 83 tons/hour (dry), circulating fluidized bed roasting furnace, multi-stage exhaust gas cleaning system

Customer benefits

Gold extraction from sorption tailings: Increasing total gold recovery through innovative roasting technology.

Significant increase in gold production: production increased by 11 %.

Compliance with strict emission regulations: State-of-the-art exhaust gas cleaning and flue gas desulphurization ensure environmentally friendly operating conditions.

With our experience in the planning and implementation of large-scale projects such as the STR system, we contribute to a sustainable improvement in gold extraction and to increasing efficiency in mining.