Technologies

BackFill® system: Sustainable efficiency thanks to innovative backfill technology

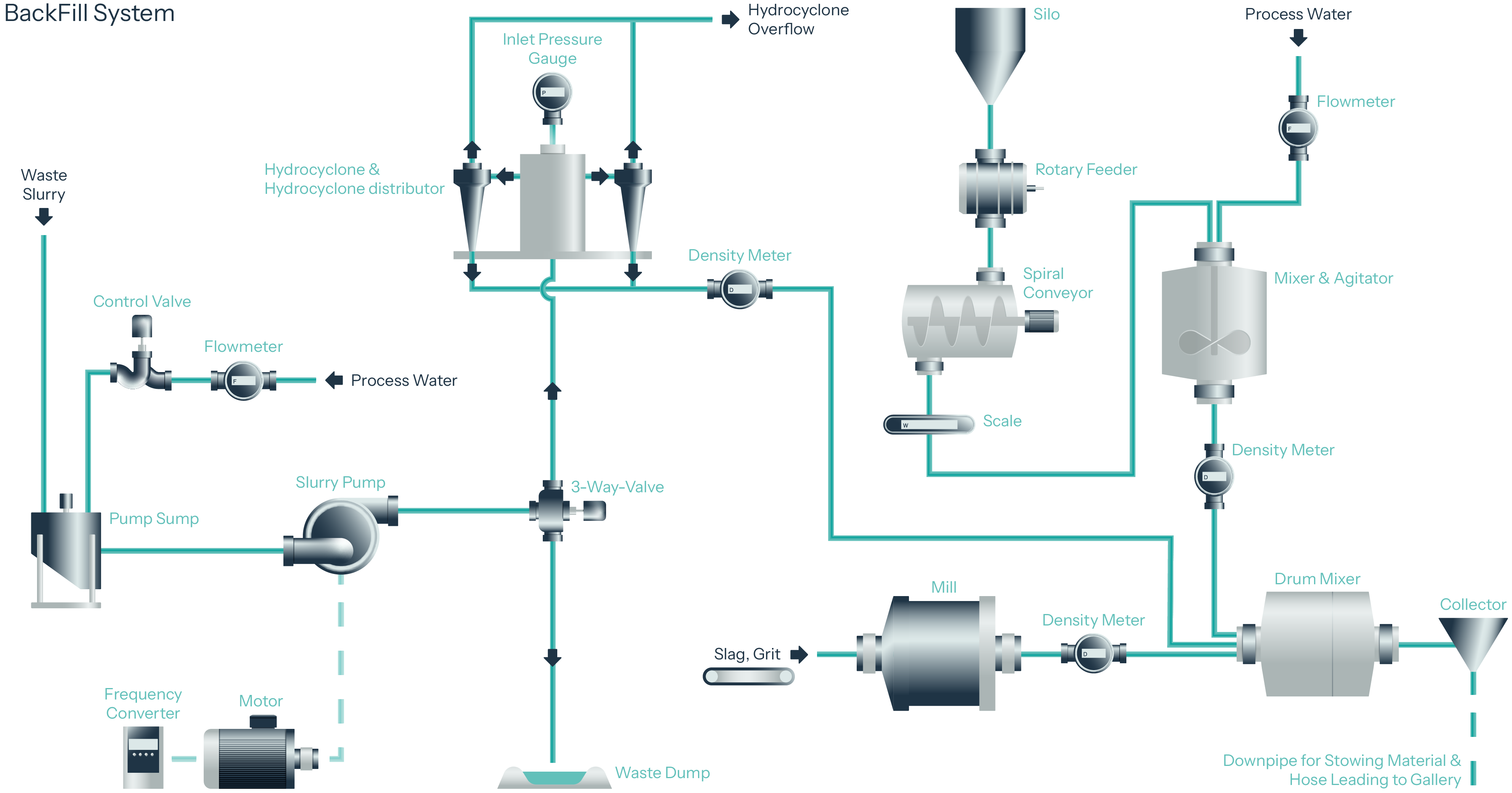

The BackFill® system from Engineering Dobersek is a modern solution for the sustainable and economical backfilling of excavation areas in mining. Based on a modular system concept, the system enables resource-saving processing and flexible adaptation to individual requirements.

A key feature of the BackFill® system is its seamless integration into existing mining and ore processing operations. By using state-of-the-art technology, backfilling is made efficient, whereby local and natural materials as well as industrial waste products can be used to produce backfill materials. This not only reduces costs, but also makes a significant contribution to environmental protection.

The system records and monitors important parameters such as the strength and flow properties of the backfill materials, the dosing of the binding agents and the transport routes. Thanks to automated control technologies, errors are minimized, operational reliability is increased and the efficiency of the entire system is maximized.

The modular structure of the BackFill® system enables customized solutions for specific requirements. The use of local resources and industrial by-products to produce backfill materials not only lowers the cost of backfill, but also reduces the burden on existing landfills.

The system ensures consistent material quality and enables backfilling over long distances of up to 2 kilometers. By optimizing the material mix and using flow improvers, cement requirements are reduced by up to 40 %, curing times are shortened by up to 30 % and the durability of the system is increased.

Possible uses and

Areas of application

The BackFill® system is ideal for backfilling excavation areas in underground mines, e.g. for the extraction of non-ferrous and precious metals such as copper, nickel, zinc, lead, gold, silver and platinum. The system is also used in ferrous ore extraction, coal processing and landscape reclamation after mining activities.

Thanks to the flexible adaptability of the system, both existing and new mines can benefit from the advantages of BackFill® technology. The use of thixotropic materials with a high solids content minimizes sediment formation and maximizes the safety of mining structures.

Despite higher investment costs compared to conventional backfill systems, the BackFill® system offers considerable economic benefits. Reduced operating costs, sustainable use of resources and increased operating efficiency lead to payback periods of just 6 to 12 months, depending on the specific application conditions.

Find out more now!

The BackFill® system from Engineering Dobersek is the ideal choice for companies looking for a sustainable, efficient and future-proof solution for backfilling. Our customized solutions ensure maximum productivity and environmental protection.

Our technologies

ContiSmelt system

Efficient and sustainable melting technology for the recovery of valuable metals.

ContiClass System

Precise classification and separation for maximum material yield and quality.

STR System

Reliable technologies for safe material transport and optimized processes in the industry.