Business areas

Engineering solutions in metallurgy: Efficient processes for sustainable metal processing

We offer you sound engineering services in the field of metallurgy. With our many years of experience and expertise in the development of technologies for pyrometallurgy, hydrometallurgy and the processing of precious metal-containing sludges, we deliver customized solutions that focus on maximum efficiency, sustainability and quality. Our technologies help to optimize raw material processing while minimizing the environmental impact.

Highest efficiency through thermal processes

In pyrometallurgy, thermal processes are used to extract valuable metals from ores and waste. We offer innovative solutions that maximize the efficiency of these processes, reduce energy consumption and at the same time ensure a high metal yield. Our technologies enable precise temperature control and thus ensure optimum melting and reduction treatment. In this way, we help to optimize the entire production process and minimize operating costs.

Gentle extraction with modern methods

Hydrometallurgy uses liquid reagents to extract metal from ores and waste. Our company offers advanced solutions that enable the environmentally friendly and resource-saving extraction of metals. With innovative processes such as solvent or acid washing, we ensure that valuable metals are efficiently extracted from mineral raw materials. Our technologies are designed to optimize water consumption and minimize the use of chemicals, thereby contributing to more sustainable metal extraction.

Pure metals thanks to state-of-the-art affinage processes

Affinage is a key metallurgical process for purifying and refining metals such as gold, silver and platinum. The aim is to achieve maximum purity (up to 99.99%) using modern processes – for example for technical applications or the economic recovery of precious metals from ores, concentrates or recycling materials.

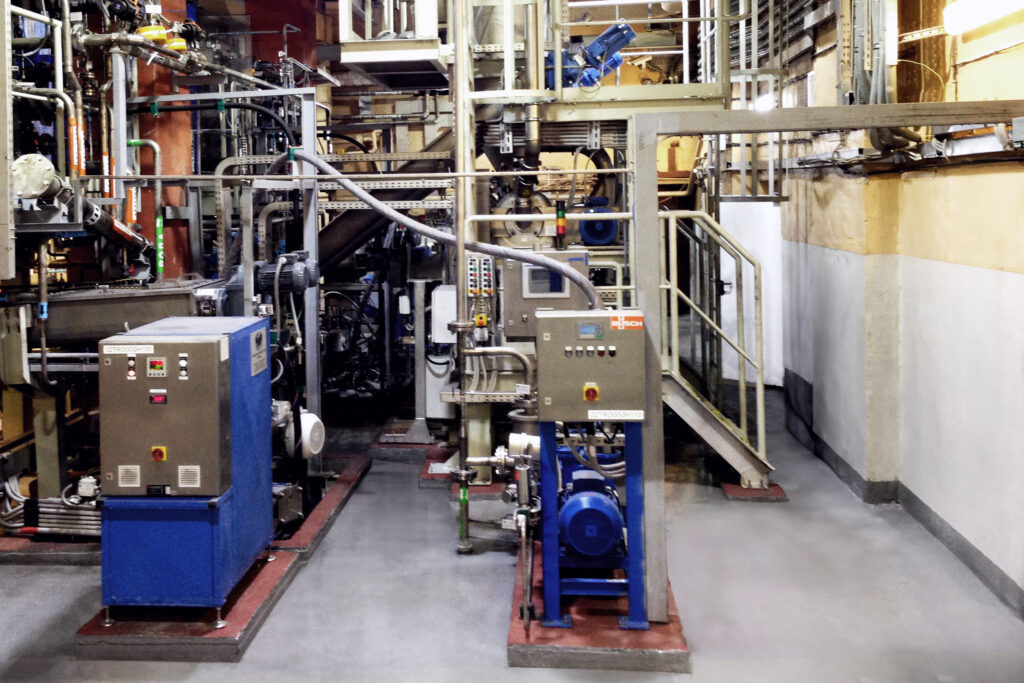

Engineering Dobersek has comprehensive technologies for refining materials with complex chemical compositions – including cathode residues, hydrated residues, gravity concentrates, anode slimes or metal-containing secondary waste. In addition to precious metal recovery, our processes also enable the recovery of valuable by-elements such as copper, nickel, selenium, tellurium and other metals. We use modern, robot-controlled systems that comply with the latest international industry standards. In this way, we offer comprehensive solutions for demanding requirements in precious metal recovery and metallurgical refining.

Sustainable processing and recovery

Processing sludge containing precious metals is a complex process that requires precise and gentle technology in order to recover valuable precious metals such as gold, silver and platinum. We offer customized solutions that enable the efficient processing and recovery of these valuable raw materials. Our technologies help to maximize the metal yield and at the same time reduce the environmental impact through gentle processes.

You can rely on our expertise and tailor-made solutions to optimize your metallurgical processes and contribute to sustainability at the same time. As a family-run company, we rely on trust and close partnerships to develop innovative, future-proof solutions together with you. Contact us today to find out more about our engineering services and how we can further improve your metallurgical processes.

Contact us to find out more about our services in the field of metallurgy. Together we will shape the future of your production – innovatively, efficiently and economically.

Our other business areas

Mining

Customized solutions for efficient mining and extraction of raw materials – from planning to implementation.

Mineral ore processing

Efficient processes for processing ores and minerals – for the highest quality and resource conservation.

Power plant technology

Reliable systems and components for modern power plants – powerful, sustainable and future-oriented.

Special systems

Individually planned special solutions for complex technical challenges – precise, flexible and efficient.