Technologies

STR®System: Optimization of gold extraction through patented technology

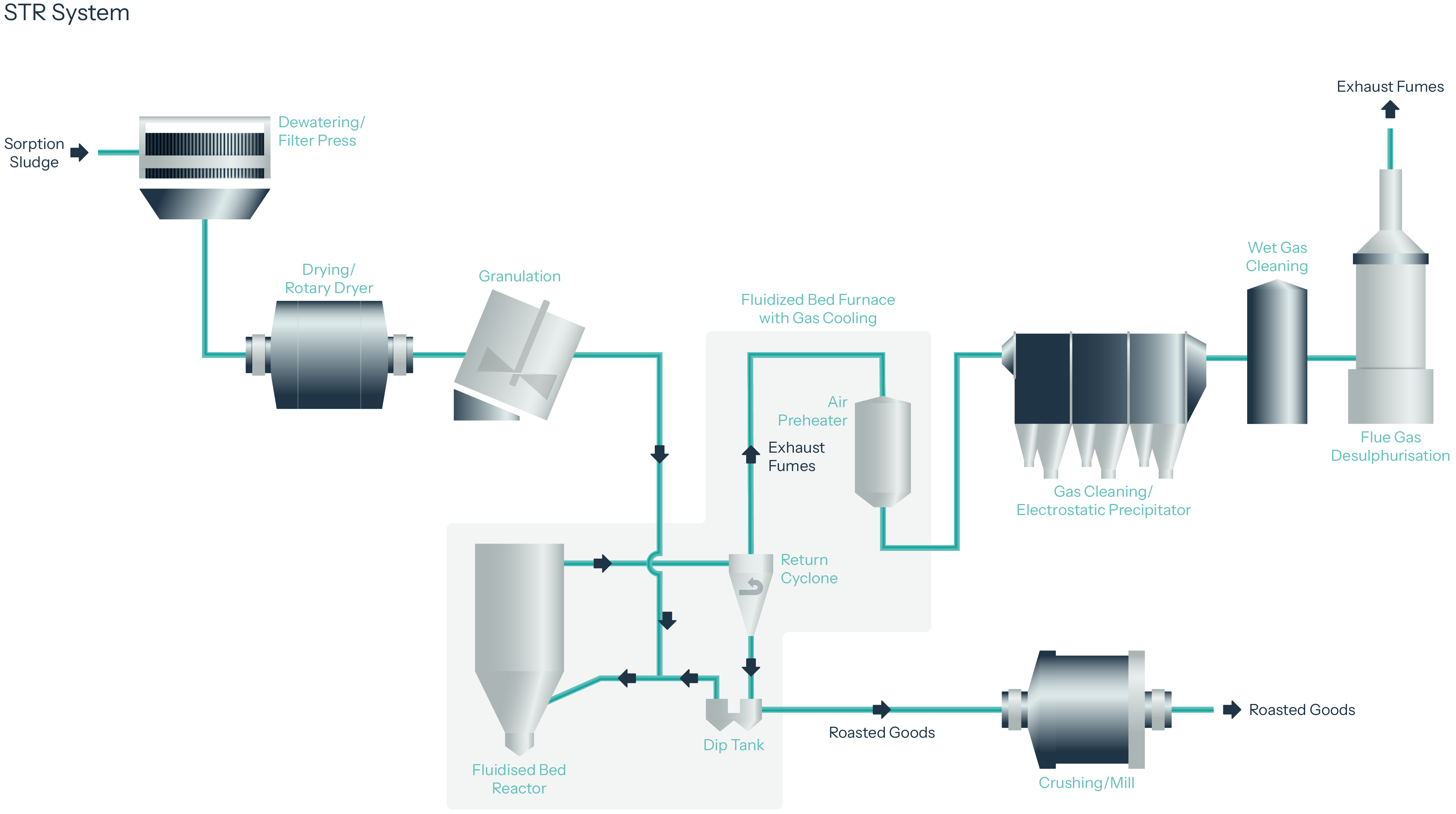

The STR®System (Sorption Tailings Roasting System) revolutionizes gold recovery with an innovative plant technology that has been specially developed for maximum efficiency and environmental compatibility. This patented solution is based on the oxidizing roasting process, which makes it possible to effectively treat previously unused residues (tailings) from the CIL process. This treatment significantly increases the overall recovery of valuable gold from the ore.

The invention relates to a method for improving the yield in a sorption leaching process for precious metal extraction, in particular for gold or silver extraction, in which the efficiency of the process is limited in particular by the content of organic carbon and/or sulphide sulphur present in the raw material, so that residual precious metal components remain in appreciable concentrations in the sorption slurries produced in the sorption leaching process. Furthermore, the process is particularly advantageous for gold-bearing ores in which the gold (usually in finely dispersed form) is present in associations with arsenic-containing sulphide minerals (such as pyrite) in addition to sulphur-containing sulphide minerals (such as arsenopyrite), and at the same time the gold recovery from the ores is significantly negatively influenced by the organic carbon content present.

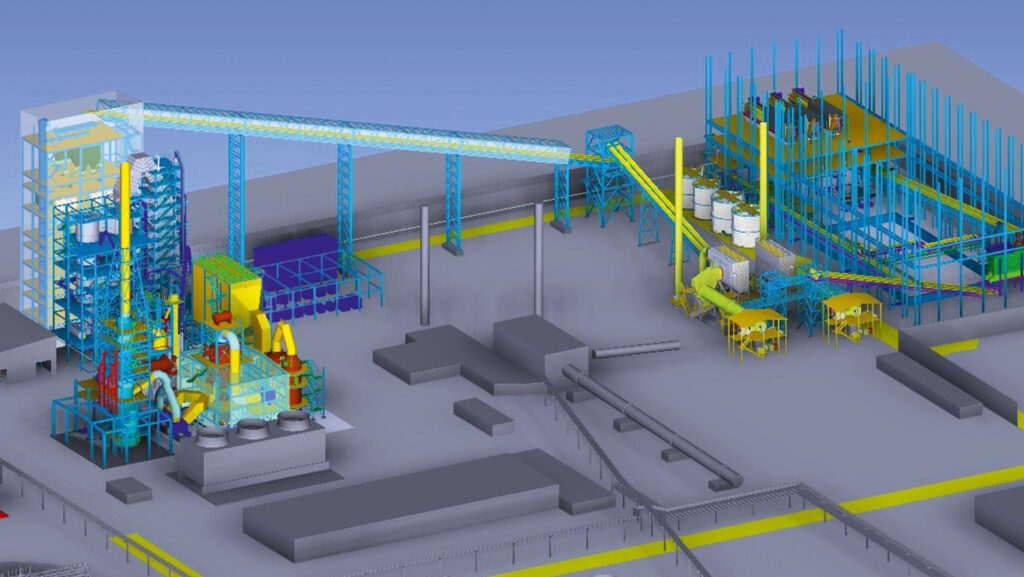

CUSTOMER: Navoi Mining & Metallurgical Combinat, Uchquduq, Republic of Uzbekistan

in detail.

At the center of the STR®System plant layout is a circulating fluidized bed furnace in which the CIL waste is roasted.

The advantages of the circulating

fluidized bed oven:

High energy density: Maximum specific capacity output per m³ oven volume

Efficient heat and mass transfer: Due to the high relative velocity between the gas and solid phases

Even temperature distribution: Ensures optimum roasting conditions for the roasting process

STR®System

system

In addition to the roasting oven, the plant includes other crucial systems and components:

- Sludge dewatering system

- Interim storage for dewatered sludge

- Drying and granulation

- Dust removal, wet cleaning and desulphurization of exhaust gases from the roasting oven

- Cooling system

- Process and instrument air supply

- Electrical equipment and automated control system

and developers.

The STR® system has been patented in several countries and regions worldwide, including Germany, South Africa, Mongolia, ARIPO countries and Eurasian countries.

This pioneering technology was developed in collaboration between Engineering Dobersek GmbH and Navoi Mining and Metallurgical Company under the leadership of outstanding experts such as Dr. Albin Dobersek and Prof. Dr. Kuvandik Sanakulov.

This innovative solution sets new standards in gold extraction technology and underlines the mining industry’s commitment to the sustainable use of resources and environmental protection.

Find out more now!

Discover how the STR®System can optimize your operations and increase your profits.

Visit us for more information and individual advice on your project.

Our technologies

ContiSmelt system

Efficient and sustainable melting technology for the recovery of valuable metals.

ContiClass System

Precise classification and separation for maximum material yield and quality.

BackFill System

Innovative solutions for safe backfilling and sustainable mining management.