References

The Mirny diamond mine operates in a permafrost area with frozen ground all year round. Phase 1 already showed that the annual sludge volumes exceeded the available landfill sites. The aim of both project phases was to drastically reduce the landfill area, increase the internal water cycle to over 95 % and keep residual moisture in the filter cake below 25 % – all without interrupting ongoing operations.

Commissioning phase 1: 2014

Commissioning phase 2: 2015

- Client: ALROSA Co. Ltd (Nyurba Mining & Processing Division, Plant 16)

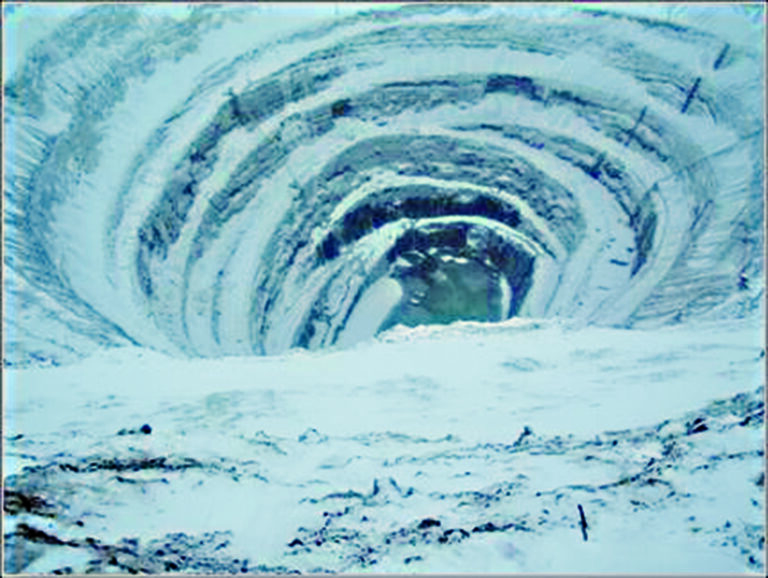

- Location: Mirny, Republic of Sakha (Yakutia), Russia

- Contract type/services: Feasibility study incl. laboratory tests, basic & detail engineering according to Russian standards, supply of equipment & technical documentation, installation supervision, commissioning, personnel training, after-sales service

Customer benefits

Reduced landfill area: five to six times less volume compared to the original landfill

High water recovery: up to 96-97 % of the process water in the circuit

Environmental protection: no new tailings ponds, protection of the permafrost ecosystem

Round-the-clock production: Fully automated lines minimize personnel deployment and downtime

Long-term reliability: monitoring and after-sales services ensure long-term system operation

Phase 1: Basic dewatering & filtration

- Components:

- Hydrocyclone cluster (24 × DN 250) for pre-thickening

- Ø 16 m Paste thickener with agitator and flocculant station

- Seven chamber filter presses for residual moisture 18-25 %

- Conveyor belt system (7× 20 m + 1× 50 m) for truck loading

- Technological pipelines, tanks (200 m³ & 600 m³), pneumatic stations

- PLC integration into existing process control systems

- Result:

- Dewatering of up to 250 t/h of sludge

- Creation of an internal water cycle of 96-97 %

- No further new landfill sites

Phase 2: Expansion to 3-stage drainage

- Supplementary modules:

- Pre-thickening: hydrocyclones (24 pieces)

- Thickening: Ø 16 m paste container with rubberized intermediate tank

- Filtration: Seven chamber filter presses with automatic air purification

- Drying: Mechanical regrinding to further reduce residual moisture

- Supply & automation: conveyor belts, process pumping stations, corrosion-resistant piping and fully integrated PLC control system

- Extended performance:

- Processing up to 6,000 tons of sludge daily

- Continuous 24/7 operation without intervention

- Residual moisture in the filter cake: 18-25 %

- Holistic approach: from pre-thickening to drying in one integrated system

- Modularity & scalability: Simple expansion for increasing capacity requirements

- Highest level of professionalism: confirmed by the official reference letter from the plant management

With these two consecutive phases,

Engineering Dobersek has realized one of the most efficient and environmentally friendly

sludge dewatering and drying lines for the diamond industry

.