References

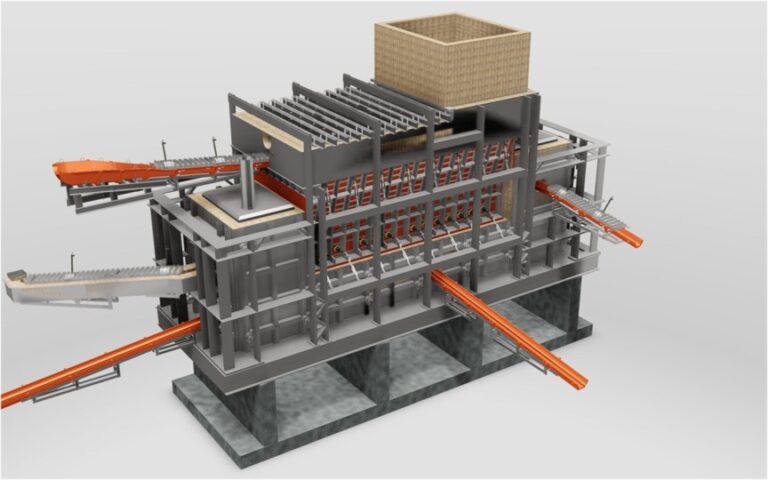

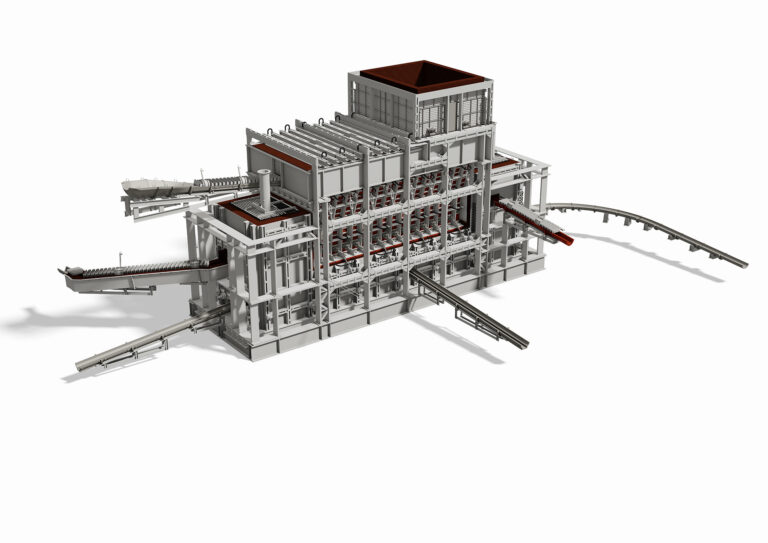

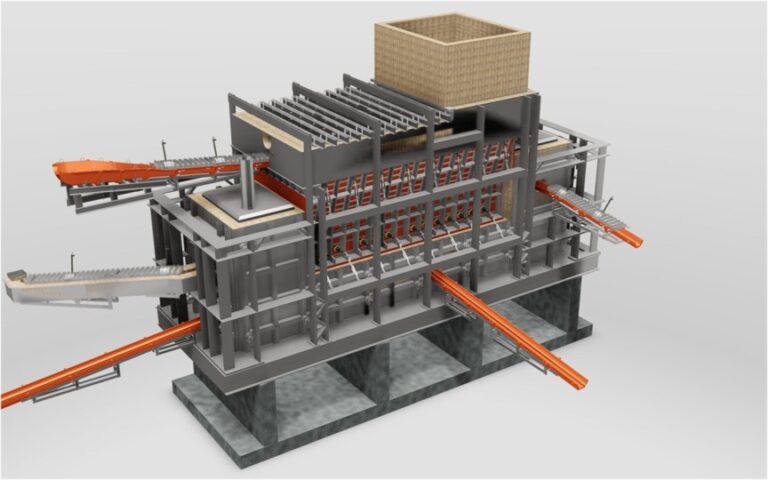

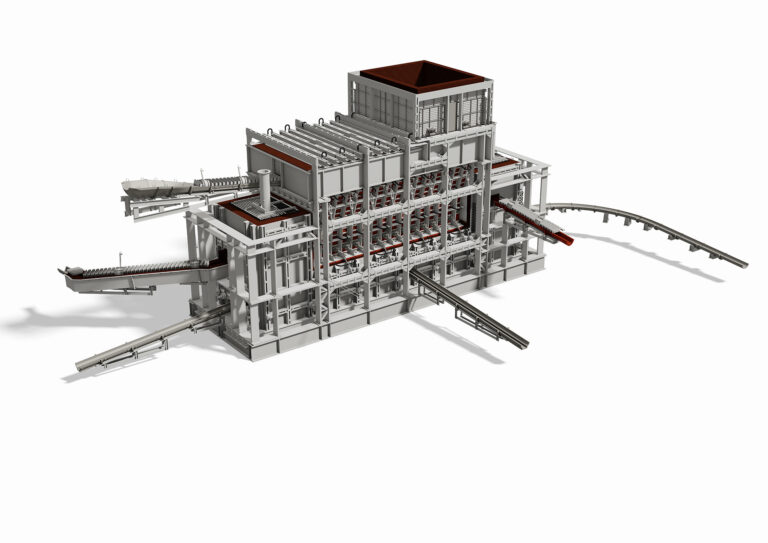

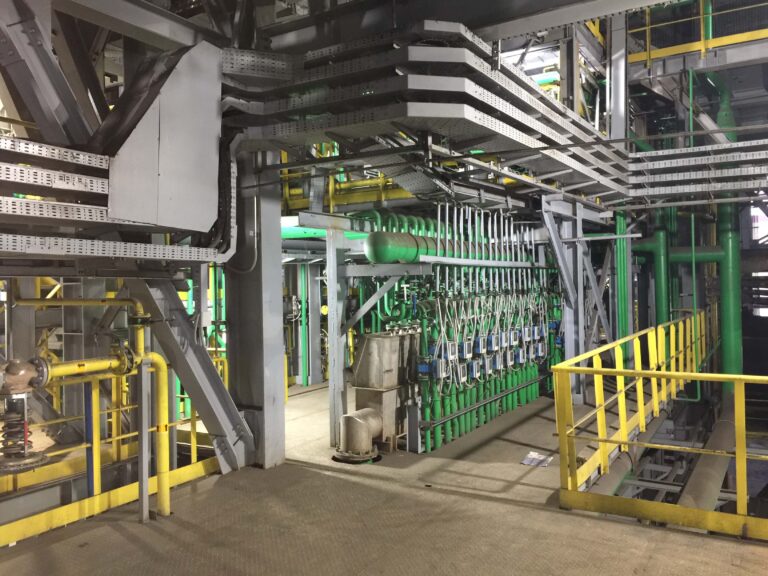

As part of a major project to modernize the copper smelting plant in Almalyk, Uzbekistan, the construction of a new Vanyukov furnace was initiated in 2014. This furnace, which enables an annual production of 73,800 tons of blister copper, represents a significant advance in efficient copper production. With the new smelting technology in the slag bath, we were able to improve both production efficiency and the environmental footprint by processing sulphurous waste gases in a sulphuric acid plant.

Commissioning: September 2018

- Client: JSC Almalyk MMC

- Location: Almalyk, Republic of Uzbekistan

- Type of contract/services: Basic and detail engineering, construction plans, programming, delivery of equipment, installation supervision and commissioning, staff training.

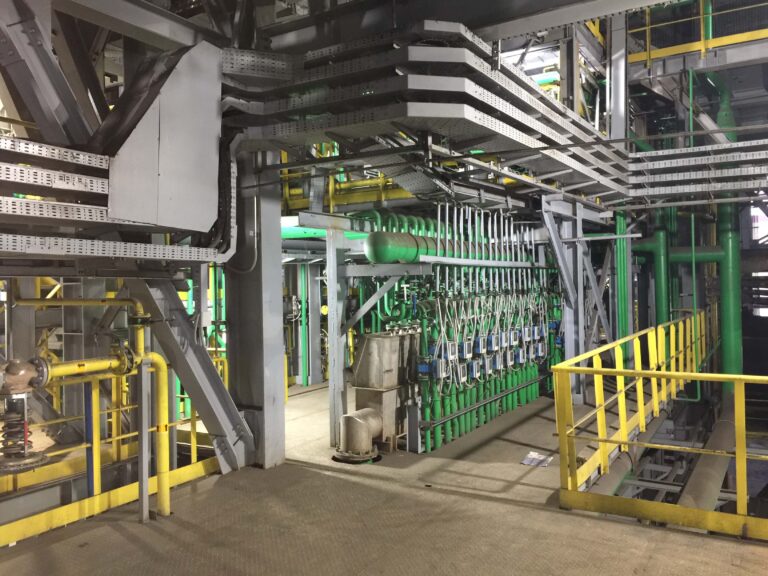

- Scope of delivery: raw material preparation, copper smelting furnace (Vanyukov, ContiSmelt® system), mixer for copper stone and slag, cleaning and cooling system for process gases, aspiration system, water treatment and cooling system, supply system for instrument air, lifting devices, electrical equipment and measuring and automation technology

- Technical data: Cross-sectional area at tuyere level: 24 m², daily melting rate: 65 t/m², furnace lining: chrome-magnesite bricks, cooling of the process gas from 1,350 °C to 380 °C by waste heat boiler

Customer benefits

Production of 73,800 tons of blister copper per year: significant increase in production capacity.

Continuous melting process: Efficient melting bath furnace technology ensures consistent production.

High copper recovery: Up to 97 % copper extraction from the raw materials.

With our expertise in plant engineering and innovative technologies such as ContiSmelt® melting technology, we have made a significant contribution to increasing efficiency and environmental friendliness in copper production.