Technologies

Conticlass® system: Increased efficiency thanks to innovative hydrocyclone technology

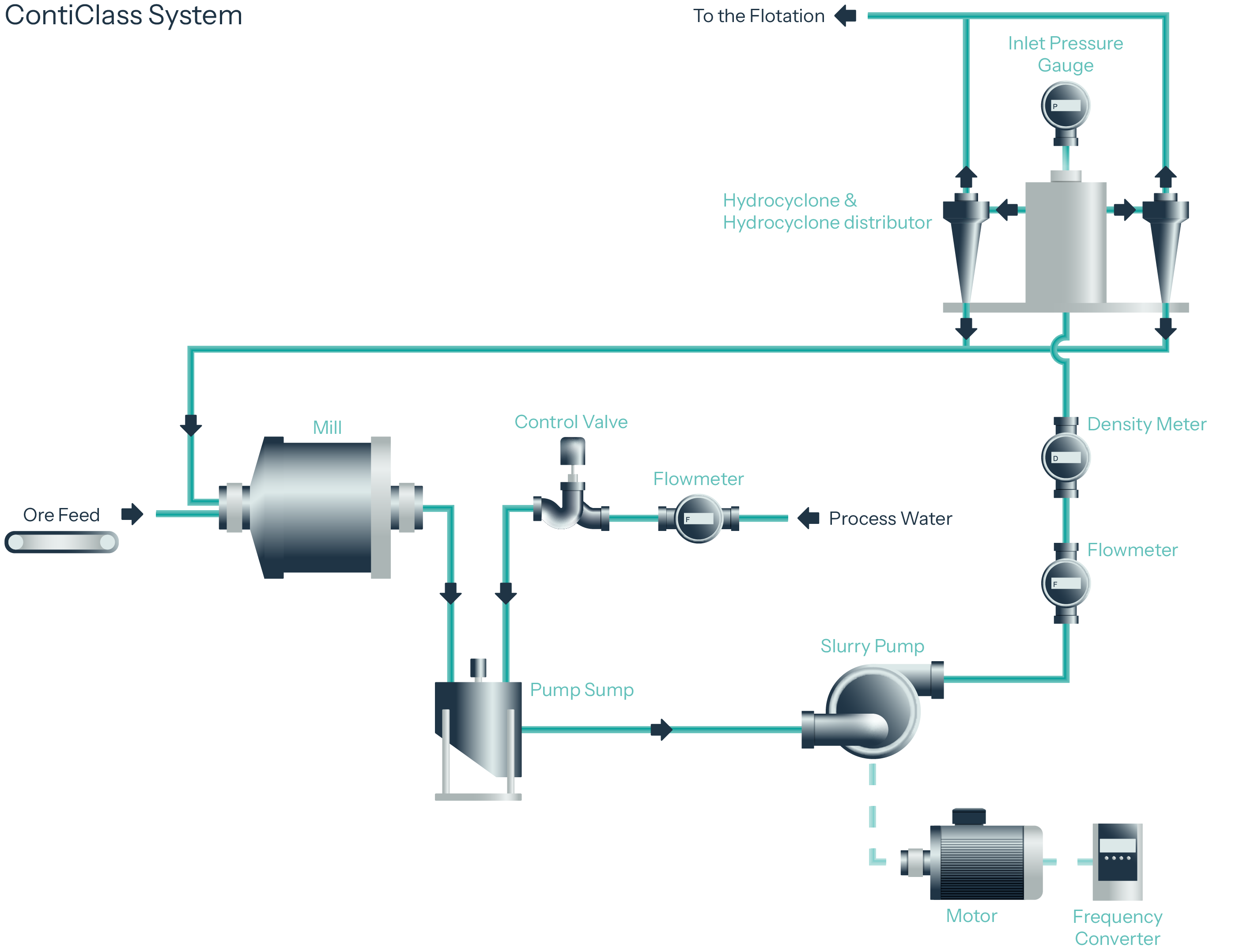

The Conticlass® system from Engineering Dobersek is a powerful ore processing solution based on state-of-the-art hydrocyclone technology. This system enables precise grain size-dependent separation processes, flexible adaptation to fluctuations in output and increased efficiency, resulting in considerable cost savings.

One of the main advantages of the Conticlass® system is its seamless integration into existing operating processes. The innovative flushing of the pipes and pumps as well as the mashing of the sump before each start-up of the pump unit optimizes operation and extends the service life of the system. To prevent the pump from running dry and to keep the level in the storage tank constant, a controlled amount of water is automatically added to the process, which is monitored and logged by a water meter. This data is displayed and archived in a visualization system together with other measured parameters such as cyclone pre-pressure, sump level, control valve position, pump speed, current consumption and ED GmbH’s patented suspension density calculation.

The system can be controlled both manually and fully automatically. Automation makes it possible to largely avoid operating errors, which increases operational safety.

In many ore processing plants, a constant supply of ore-bearing earths is not always guaranteed. Fluctuations in the feed quantities can often only be compensated for by switching several mills and pumps on or off. This is not necessary with the Conticlass® system. Thanks to a speed-controlled pump with a flat characteristic curve, the system can handle flow rates of up to 950 m³/h with just one pump. This ensures a constant pressure at the hydrocyclone inlet, resulting in consistent flow conditions and product quality.

By using the latest cyclone technology, the Conticlass® system improves separation performance by up to 10%, which significantly increases the efficiency of the overall process. This not only reduces the use of flotation agents, but also increases the throughput of the mills by up to 15 %. In addition, the pump’s integrated dry-running protection and the optimized control of the process parameters ensure that wear parts achieve an operating life of up to 4,000 hours. This reduces maintenance costs and lowers energy consumption by up to 50 %.

Possible uses and

Areas of application

The ContiClass® system is ideal for the extraction of non-ferrous, precious and heavy metals such as copper, nickel, zinc, gold, silver and platinum. It is also used in iron-mineral ore extraction, phosphate processing, coal processing and quartz sand extraction. Thanks to its high flexibility, the Conticlass® system can also be integrated into existing plants for various process technologies.

Another area of application is tailings backfilling, where contaminated wastewater sludge is separated from particles smaller than 20 µm. These fine particles are unsuitable for backfilling - our ContiClass® system ensures that they are reliably removed through precise separation and control of the separation process.

Although the Conticlass® system requires higher investment costs compared to conventional separation systems, it offers considerable economic advantages. Due to the efficient process design and the significant increase in production, payback periods of only 6 to 12 months can be achieved, depending on the products obtained. Customers report that the additional costs compared to conventional systems are often offset by the production increases and cost savings after just a few months.

Parameters such as the hydrocyclone inlet pressure, the suspension density and the circulation rate play a decisive role for optimum process control. The Conticlass® system monitors and controls these parameters automatically, resulting in a significant improvement in process performance. Flexible adaptation to different ore applications and fine adjustment of the separation conditions not only increases the metal yield, but also the overall performance of the processing operations.

The Conticlass® system from Engineering Dobersek offers a modern, efficient and flexible solution for metal and ore processing. Thanks to the speed-controlled pumps and modern hydrocyclone technology, the efficiency of the separation processes is optimized, operational reliability is increased and production costs are reduced. The high flexibility and adaptability to different operating requirements make the Conticlass® system the ideal choice for companies looking for a sustainable, efficient and future-proof solution.

Find out more now!

The Conticlass® system from Engineering Dobersek offers a modern, efficient and flexible solution for metal and ore processing.

Visit us for more information and individual advice on your project.

Our technologies

ContiSmelt system

Efficient and sustainable melting technology for the recovery of valuable metals.

STR System

Reliable technologies for safe material transport and optimized processes in the industry.

BackFill System

Innovative solutions for safe backfilling and sustainable mining management.