Technologies

ContiSmelt® System: Innovation in continuous melting

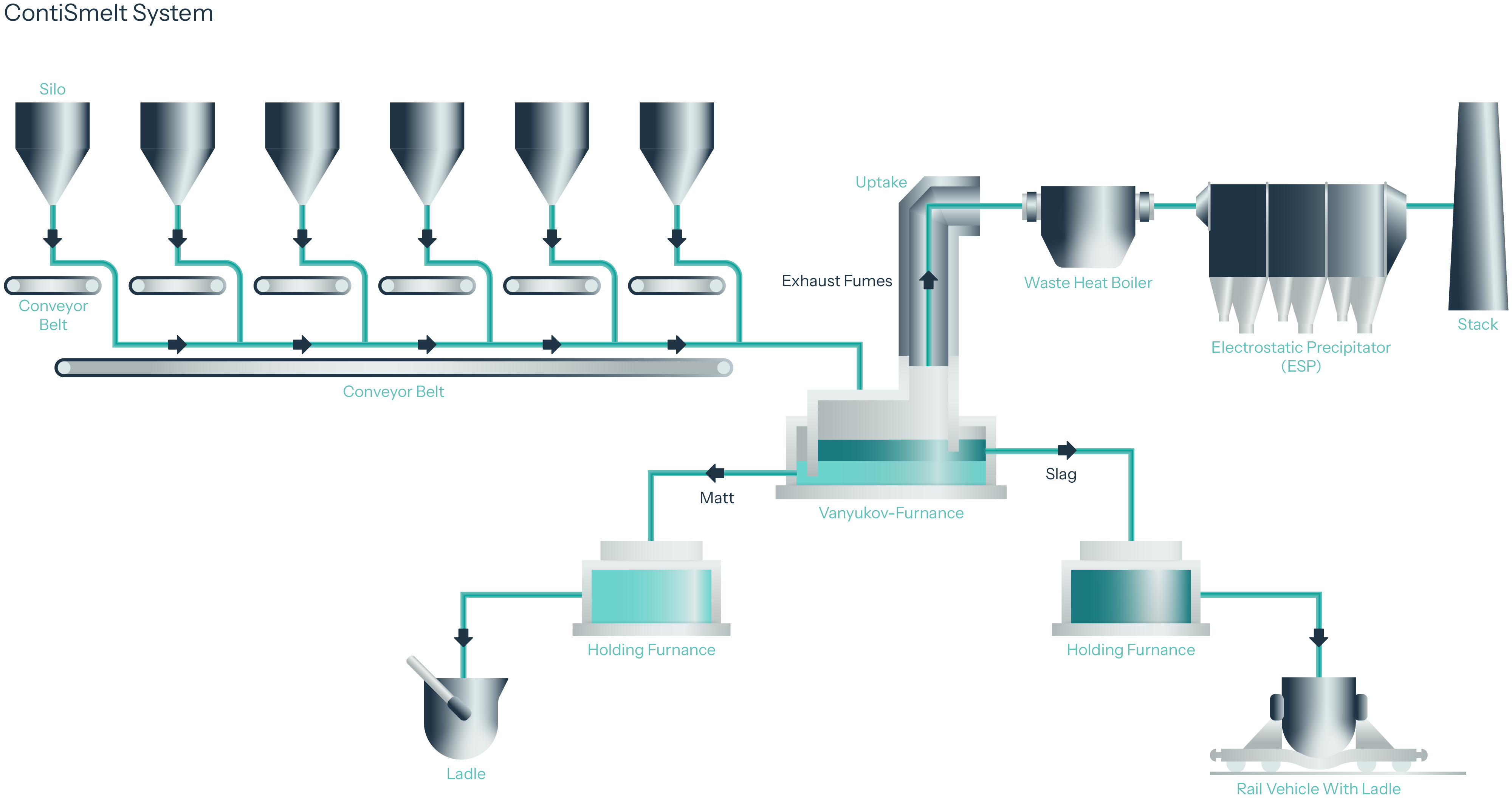

Welcome to the future of the melting process with the ContiSmelt® system, a groundbreaking technology developed by Engineering Dobersek. “ContiSmelt” stands for continuous melting and represents a revolutionary system layout based on the proven Vanyukov process. At the center of this system is our state-of-the-art melting bath furnace.

Advantages of the

ContiSmelt® system

Continuous melting process: Our melting bath furnace technology ensures a continuous melting process that increases efficiency and productivity.

Simple preparation and dosing: The handling of the process-specific mixture of concentrates and fluxes is significantly simplified. Elaborate processes such as intensive drying, grinding and thorough mixing are no longer necessary, saving costs and time.

Optimized heat and mass transfer: The active mixing of the melt significantly accelerates mass and heat transfer in the melting process. This leads to an almost thermodynamic equilibrium and thus maximizes the process intensity and the performance of the furnace.

Sustainable use of waste gases: The waste gases produced during the melting process are rich in SO2, depending on the oxygen enrichment. These valuable waste gases can be used to produce sulphuric acid and thus make a sustainable contribution to conserving resources.

The ContiSmelt® system comprises not only the melting bath furnace, but also other essential sections:

Find all the tools you’ll need to create advanced websites in one place. Stop wasting time searching for solutions.

Add more power to Elementor using our creative elements and make your projects look prettier than ever before.

We strive to innovate when it comes to functionality. Our mission is to be the best, come and join the ride.

A toolkit of essential widgets and features that will supercharge your workflow

automation system

The ContiSmelt® system is equipped with a modern, integrated, multi-level automation and information system.

It was developed entirely on the basis of the SIMATIC PCS7 process control system from Siemens, which is one of the best and most widely used process control systems in the world.

The main advantages of this control system are based on homogeneity – the methods of data management, the organization of industrial communication and the implementation of configuration processes are uniform.

These advantages also come into play during commissioning, operation and maintenance of the finished system, during repair work and, of course, during modernization.

Another important advantage of the control system for the ContiSmelt® system is that there are many skilled workers who are familiar with the operation of Simatic PCS 7, which is not an unimportant factor in a new production plant.

The three-level structural control system is a series of geographically and functionally distributed subsystems with a single information space in which each subsystem can use the parameters and calculation results of other subsystems.

The top level is the level that implements the functions of operational control (dispatcher control) and control of the technological object represented by software and hardware of computer devices designed to collect, store, process (summarize) and display significant amounts of information.

The middle level is a level that implements the control, regulation, emergency protection and interlocking functions; this level is represented by a PLC.

The lower level is the level that implements the functions of receiving and primarily converting information about the course of technological processes and the operating status of devices, which are controlled by devices such as sensors, valve actuators, actuators, control devices and other instrumentation and automation (including automation devices built into technological equipment).

The main objects of automation are:

- Preparing and loading the oven with the load

- Supplying the oven with gas, air and oxygen

- Water supply for cooling the oven

- Mixing furnaces for stone and slag Cleaning and cooling of process gases

- Water treatment and cooling system

The ContiSmelt® system is the answer to the challenges of modern metallurgy. Thanks to its innovative approach and versatile advantages, it represents a future-proof solution that focuses on both economic and ecological aspects. Let’s explore the possibilities of this advanced technology together and take your production processes to a new level.

Find out more now!

Discover how the ContiSmelt® system can optimize your operations and increase your profits.

Visit us for more information and individual advice on your project.

Our technologies

STR System

Reliable technologies for safe material transport and optimized processes in the industry.

ContiClass System

Precise classification and separation for maximum material yield and quality.

BackFill System

Innovative solutions for safe backfilling and sustainable mining management.