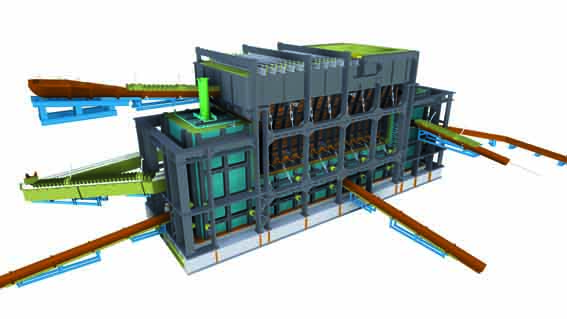

SMELTING BATH FURNACE

Central of the ContiSmelt System plant design with extensive periphery is a smelting bath furnace.

The advantages of ContiSmelt®System:

- A continious, reliabele smelting process with simultaneous reduction of pollution is ensured by the smelting bath technology.

- The preparation of concentrates and fluxes are cost-efficient and simple, because the complex drying and grinding is no longer necessary

- A high power output is achieved by mixing the melt with blast air and a specially adjusted oxygen concentration on it

- The active mixing of the melt accelerates the mass and heat transfer in the smelting process of the raw materials (almost thermodynamic equilibirium)