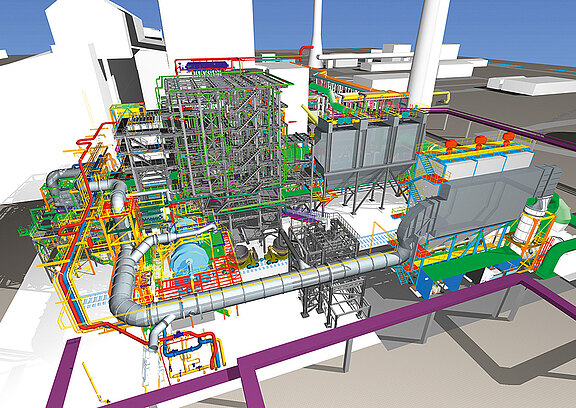

Customer

JSC Almalyk MMC, Almalyk, Republic of Uzbekistan

Commissioning

December 2016

Services

Basic and detail engineering, construction documents, programming, supply of equipment, on-site construction and installation works, installation supervision and commissioning, training of personnel.

Scope of supply

- Feed preparation and dosing system

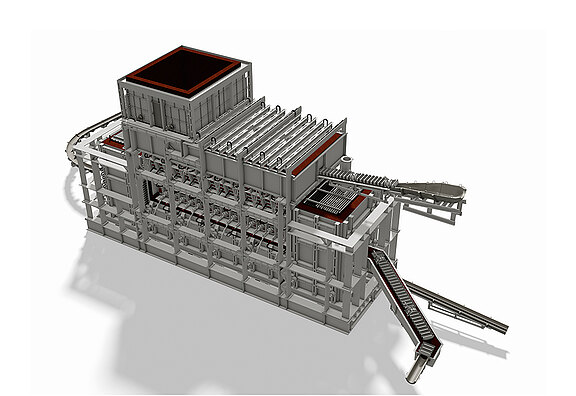

- Smelting furnace as main part of ContiSmelt®System

- Matte mixer and slag mixer

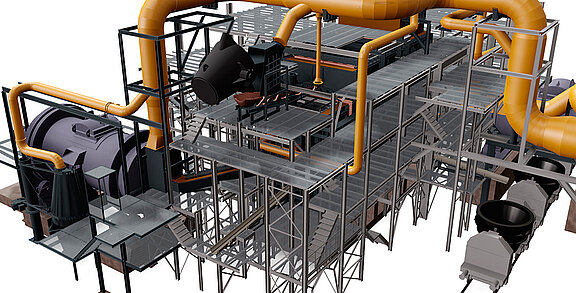

- Systems for cleaning and cooling of process gases

- Aspiration system

- Water treatment and cooling system

- System for supply of technological and instrument air

- Main lifting equipment

- Electrical equipment and instrumentation

- Automated controll system

Technical data

- Sectional area at tuyere level: 24 m²

- Furnace width at tuyere level: 2.5 m

- Discharge of slag and matte: via siphons

- Furnace lining: Chrom-magnesite bricks

- Walls and vaults: water-cooled caissons

- Number of tuyeres: 28 pcs.

- Daily average specific melting rate at the level of blowing tuyeres: 65 t/m2

- Waste heat boiler (calibrated pipes) for cooling of process gases with a temperature of: 1,350 °C to 380 °C

- Mixer matte/slag: each 200 t

Customer benefits

- Production of 73,800 t blister copper/ year

- Ensuring of a continuous smelting process with a bath smelting technology

- Recovery of copper matte: till 97%