Customer Kazzinc Ltd.

Main investor Glencore International AG

Engineering 2006 - 2008

Installation 2008- 2010

Commissioning 2011

Services

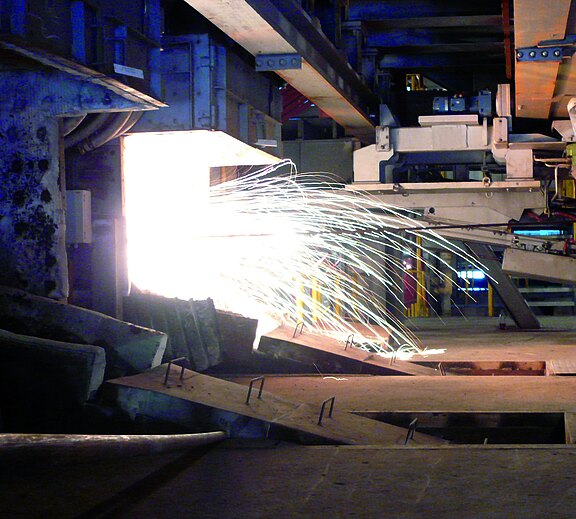

- Construcion of the new copper plant

- Modernisation of existing lead plant

- Extension of the sulphuric acid production

Scope of supply

Copper plant

- Feed preparation

- Gascleaning and dust treatment

- Electric furnace

- Matte converting, process gas cooling system

- Anode furnace and anode casting wheel

- Gas aspiration system

- Cooling water system

- Pressure air system, oxygen and nitrogen supplying system

- Fuel system (diesel and heavy oil)

- Anode sludge leaching system

- Anode sludge drying system

- Auxiliaries

Lead plant

- Slag casting line

- Batching mould

- Electro filter

- Gas channel system

- Smelter ventilation and heating system

Technical data

- Copper plant

Production of 87,500 t/year copper cathodes

Lead plant

Production of 100,000 t/year

Customer benefits

- Starting copper production in new copper plant

- Higher productivity and quality improvement in lead production

- Task “Emission of harmful substances from new plants must be lower than from old plants" was fulfilled

- Reduction of air pollution, utilisation of gases from the lead smelter in sulphuric acid production

![[Translate to Englisch:] Jetzt mehr erfahren Coal.jpg](/fileadmin/images/dobersek/Icons/Coal.jpg)