Customer Alrosa, Russia

Commissioning July 2015

Services

Feasibility study incl. laboratory tests for the production of filter cake, basic- and detail engineering, supply of equipment, supervision of mounting, commissioning, training of operating staff, after-sales-service

Scope of supply:

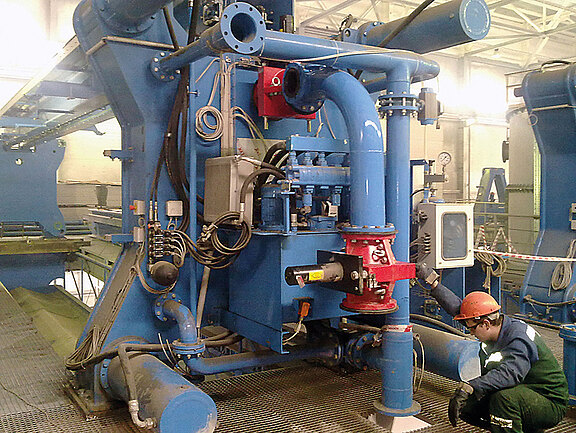

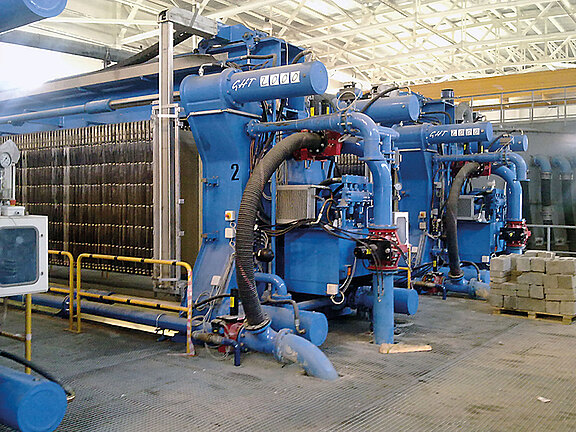

- 7 chamber filter presses incl. high-pressure slurry pumps

- 2-stage thickening including slurry pump units:

- Hydrocyclone station “ContiClass®System” with 24 pcs. cyclones DN250

- Ø 16 m paste thickener with flocculant station

- Rubber lined intermediate tank with agitator

- Conveying systems to the truck loading bunker

- Compressed air supply station for the cleaning of the filter cloths

- Wear-resistant pipelines for PN16

- Values with pneumatic drives

- Pump station for the process water

- Integration of the new control system in the existing plant automation

Technical data

- Throughput of solids: 6.000 t/day

- Operation 7 days/week

- Residual moisture of filter cake: 18 – 25%

- Pressure of slurry pumps: up to 15 bar

- Waschwasser Druck: 50 bar

- Pressure for cleaning of filter cloths: 10 bar

Customer benefits

- Installation and commissioning of dewatering system without interrupting the production

- Process water recovery up to 97%

- Reduction of disposal site area: 5 to 6 times less than before

- Dumping is no more applicable because of the detoxified dry cake material that is usable for road construction