Customer MMC Norilsk Nickel, Russia

Commissioning 2014

Services

Basic und detail engineering, project design according to Russian standards, preparing the project documentation as well as the documentation for civil and steel works, programming of the automatic control system, civil works, mounting, commissioning, staff training

Scope of supply

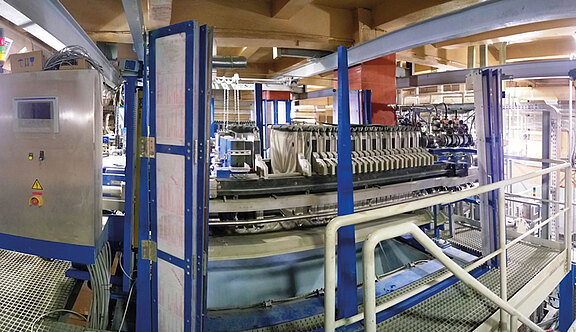

- 2 filter presses incl. peristaltic pump aggregates

- 2 vacuum dryers

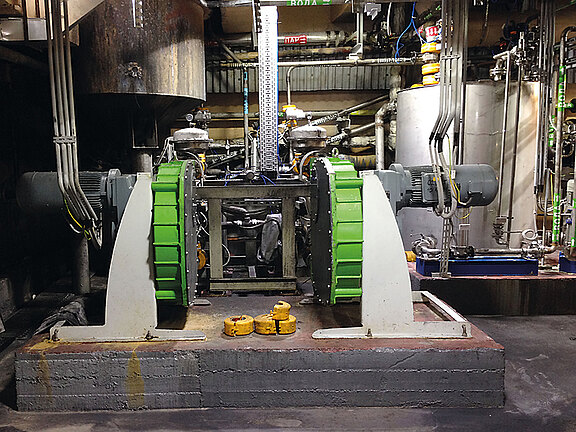

- 2 mills for post grinding of thickened sludge

- 1 packing machine for slurry into PVC bags incl. loading bunker, precision scale for the exact filling, machine for welding PVC bags, aspiration system, label printer and conveyor belt for the transport of bags

- Compressed air preparation and supply station for the de-dusting of filter cloths and the ventilation of filter cake

- Wear- and acid-resistant titanium slurry pipings and stainless steel pipings for water and air supply

- Full corrosion-resistant valves and pneumatically and electrically driven equipment

- Pump station for process water with water tank and steam-heating of the water inside tank

- Process and electro technical equipment

- Automation system based on SPS from “Allen Bradley” and “Siemens”, process visualisation and archiving of data, data transfer to existing plant network by using ethernet TCP/IP-protocol

Technical data

- Dewatering of anode sludges from eleсtrolysis of copper plant

- Throughput: 10 m³/2h with solid content of 8 - 10% acid medium

- Residual moisture of material after filter press: 16-25%

- Residual moisture of material after vacuum dryer with t=90-140°C: < 3%

- Grain size of thickened sludge: < 1 mm

- Packaging of PVC bags with net weight each bag: 24.5 kg +/-50 g with an accuarcy of 0.1 g

- Total output:: 800 - 1200 kg/8h shift operation

- Installed electric power: 374 kW

- Electrical devices: 237 pcs

- Monitoring stations: 204 pcs