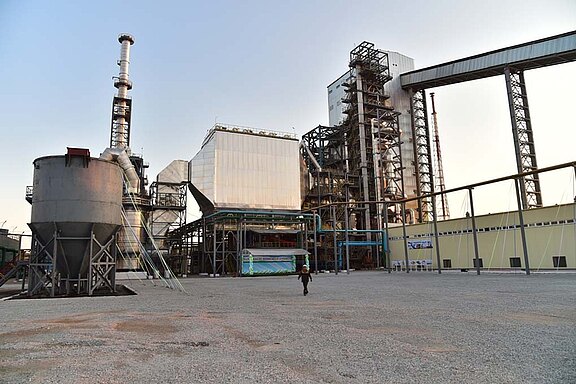

During the festive ceremony Dr. Albin Dobersek – Managing Director and founder of Engineering Dobersek – handed over the plant for the roasting of gold containing sorption tailings to the Uzbek Customer Navoi Mining & Metallurgical Combinat.

Ambitious challenge mastered by German Engineering

Along with the STR System (Sorption Tailings Roasting System), the process developed and patented by Engineering Dobersek, the Customer obtains a very innovative worldwide unique large-scale plant. Extensive field trials and various testings, carried out by Engineering Dobersek, have proved the oxidizing roasting to be the best process to gain valuable materials from the tailings. This approach of the company was crucial for NGMK in 2017 to award the contract for the implementetion of the whole process, engineering, delivery of all techncal equipment, supervision works and commisioning of the turnkey plant to Engineering Dobersek.

The technical solution offered by the German company generates a very important value for the customer: optimization of gold roasting process while taking enviromental concerns into account. Thanks to the roasting of sorption tailings, determined by the STR System, NGMK´s gold recovery can be significantly increased. The processing of up to 83 t/h dry tailings is possible. Using of e-filters, wet scrubbing of exhaust gas including wet e-filters and the application of the first gasdesulphurisation plant enables NGMK to comply with strict exhaust gas regulations of Usbekistan.

After 35 years of fruitful work on the international market Engineering Dobersek continues its success story, having gained another essential reference in the field of metallurgy.